Many pieces here are designed to be indoors, but there’s no wind? Propulsion, making a piece move, can be done several different ways. There are several solutions below, but some owners are also happy with just opening the windows.

Digital Bases

Placing Kinetic pieces indoors has always frustrated me because there is no wind and hence no natural movement. I’ve worked on several different solutions (see below) all of which were lacking until now.

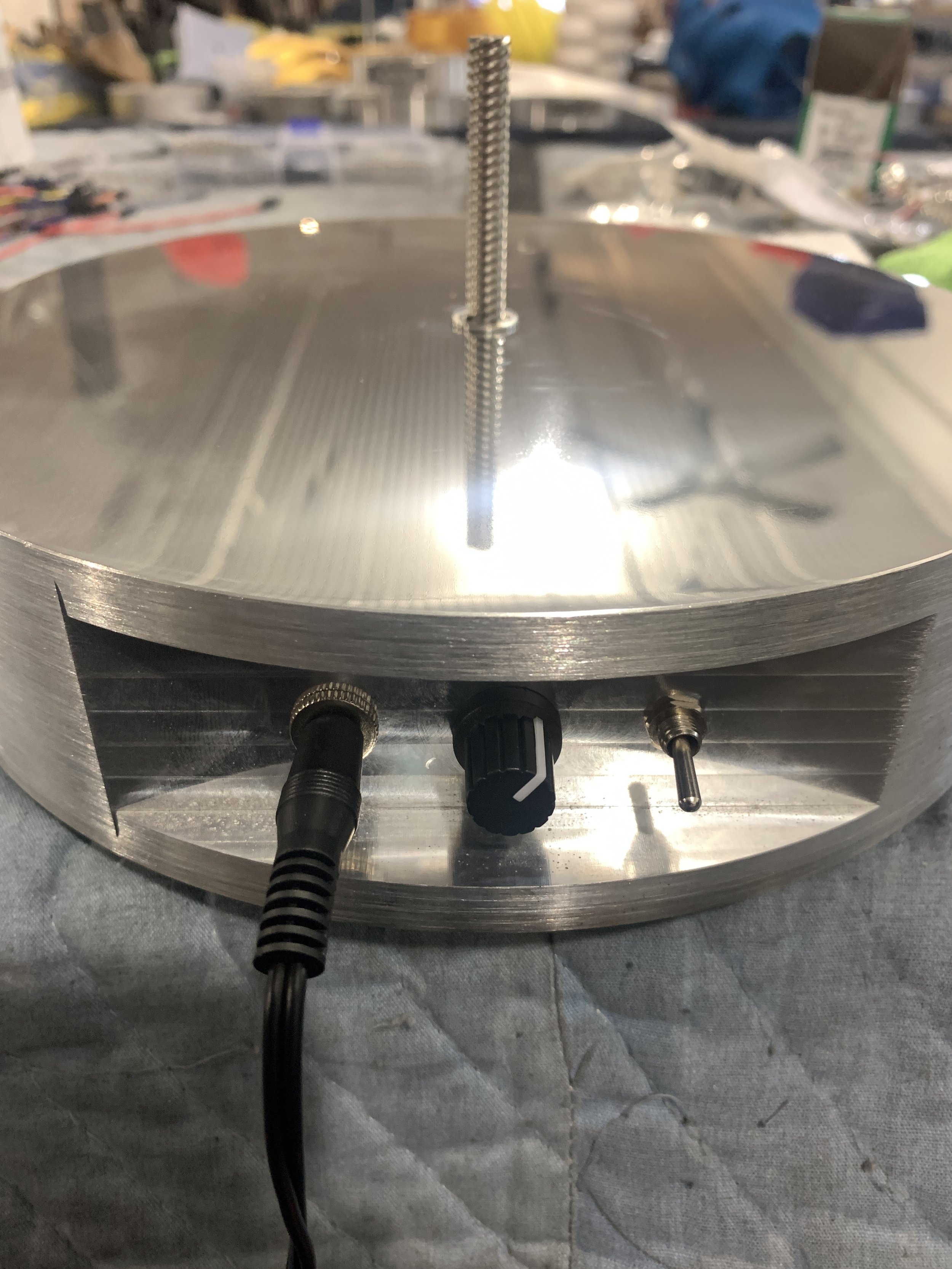

The most recent solution is to create a powered base controlled by a stepper motor, driver and micro computer circuit. Rather than just turn and reverse, computer code allows me to use direction, speed, acceleration and deceleration to create a unique pattern of movement for each piece. For the current Ribbon Stacks this program lasts for more than 2 minutes before it automatically repeats.

Most important for residential destinations, these bases are absolutely silent.

For the January 2023 Octavia Show the Ribbon Lamps and all of the 3D Printed pieces were on Digital Powered Bases. At left is the powered base for metal sculpture where the motor and all electronics are built into the base. For 3D Printed Pieces the electronics are in a separate box.

I fully expect this design to be integrated with the vast majority of indoor work over the next year.

Turntables

Using a turntable as a means of propelling Kinetic Sculpture indoors isn't new, but I haven’t seen this application before.

Pictured is new, very inexpensive turntable available from Amazon that works very well for some, but not all of the work here.

Timers

One of the things I’ve become all to familiar with is the wide range of timers available, how they work and why some are better than others. For either Pedestals or Turntables any one of a number of timers can control when things kick off and when it’s time to stop. It’s easy, for example, to enable a sculpture from 7am to 9 am in the morning and then again from 6pm to 10pm in the evening. And weekends can be different.

Pedestals

One of those early ideas that seemed at the time to be a good solution. These pedestals were very good for my first gallery show and also very handy in the studio. But ultimately these pieces were too big, too heavy, too expensive and too loud to really work.

This first solution was to design a pedestal base that provided propulsion. Inside are two large industrial inline fans that have PWM-controlled EC Motors. The fans are quite powerful but we don’t go past 40% to keep sound to an absolute minimum.

The nature of these fans, because of digital control, is the slow ramp up to speed rather than turning instantly on, which improves the random effect of the airflow. Supplies for sculpture come from a wide range of industries - in this case the fans were originally commercialized for cannabis growing operations.